PRODUCTS

FRP Grating and Structure Products

FRP Grating / Handrail

WHY CHOOSE STRONGWELL

Experience

Strongwell produced pultruded products for the first time in 1956. In 1959, the company produced the first ladder rail and later produced more than one billion feet. It was the first to develop a line of standard structure types (EXTREN®) and in the 1970s it provided the first pultruded grating. For many years, Strongwell has developed hundreds of proprietary and customized products in many markets around the world. Strongwell has achieved successful growth and is recognized as the "golden standard" for pultruded products. Strongwell's trade name is recognized worldwide.

Engineering Capability

Strongwell has superior technology in all applicable engineering fields compared to other homologs. Professional structural engineers design structures or provide technical support to customers. Mechanical engineers perform equipment, mold design and FEA analysis on actual or proposed pultruded parts. Electrical and systems engineers design systems and electrical components that make equipment more efficient. Chemical engineers and chemists are confident that many resin systems used by Strongwell are suitable for operation. Engineers perform key positions in sales, marketing, manufacturing, quality assurance and general management.

Size / Capacity

Strongwell has over 65 molding machines. It ranges from being capable of producing very large parts (eg 36 "double web beams) up to 40 lines at a time, to extracting very large parts. This machine has four Strongwell The facility is housed in more than 730,000 square feet of manufacturing space, which allows Strongwell to supply the amount of products customers need, and the flexibility to quickly respond to tight schedules.

Product Range

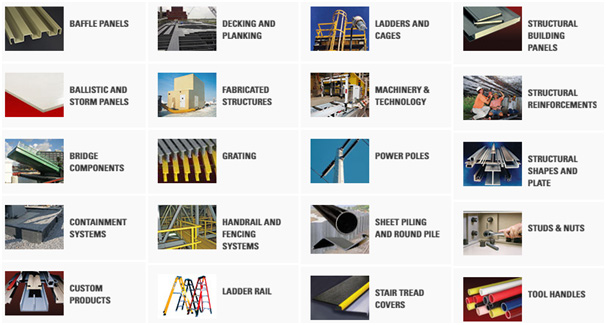

Strongwell is one of the world's largest, including standard structural shapes, plates, gratings, planking, handrail systems, building panels, ballistic resistant plates and systems, power poles, nuts and bolts, cooling tower components, ladder rail, We have proprietary fiber-reinforced structural products. We also have hundreds of customer-owned die sets and tool sets for custom parts. A broad product range means more products are sold and more products are selected to optimize the solution.

Quality and Testing

Strongwell has a 10,000 square-foot laboratory and research and development center in Bristol, Virginia, and a small laboratory in Chatfield, Minnesota. Strongwell has its own ability to perform most ASTM tests for pultrusion. The company leverages vendor testing and R & D centers that complement the composite testing and testing capabilities of the University of Tennessee and Virginia Tech. Strongwell's US facilities are ISO 9001 certified by DNV-GL. The company adheres to strict procedures and protocols and adopts the concept of Total Quality Management (TQM) in all aspects of the business.

Made in the USA

All Strongwell products sold are made exclusively in the United States, ensuring the highest quality and appearance for those who are proud to work.

WHY CHOOSE FIBERGLASS

What is Fiberglass Reinforced Polymer?

Fiberglass Reinforced Polymer (FRP) is often referred to as "fiberglass". The "glass fiber" used in this sentence is a composite composed of a polymer matrix reinforced with glass fiber. The strength of the glass fiber part is mainly determined by the type, orientation, amount and location of the glass fiber in the composite.

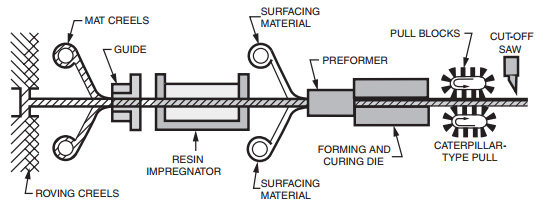

What is Pultrusion?

Pultrusion is a manufacturing process for producing continuous lengths in the form of reinforced polymer structures with continuous sections. The process involves stretching the raw material, the liquid resin mixture and the tempered glass fiber through a heated steel forming die using a continuous pulling device.

The Features of Strongwell’s Fiberglass Composites

- High Strength - Stronger than structural steel, used in building structures, passages, platforms, etc.

- Light weight - Strongwell's fiberglass composites are about 75-80% less than steel and 30% less than aluminum. This lowers transportation costs, facilitates installation and reduces weight when designing the structure.

- Corrosion resistance - Strongwell's proprietary "wet" process ensures perfect reinforcement saturation. Fiberglass does not decay and is not affected by insects and a wide range of corrosive environments. Strongwell FRP composites have been used successfully in indoor and outdoor applications in hotels, restaurants, chemical plants, water and wastewater treatment plants and many other corrosive environments.

- Low conductivity - Good insulating glass fiber is widely used in electrical applications due to its low thermal and electrical conductivity

- Electromagnetic transparency - Glass fibers are transparent to radio waves, microwave ovens, and other electromagnetic waves. Strongwell composite products are used in communications applications due to this feature.

- Sales team 1

- IAN JEONG

- T. 82.51.462.2555

- M. sa3@worldocean.co.kr

FRP Grating / Handrail

- Duragrid Phenolic Grating – Walkways and Access Platforms-Skid grating, FPSO turrets

- Duragrid Phenolic - Stair treads

- Duragrid Phenolic Nosing for landings

- Duragrid ET-5000 - Crane Boom service walk

- Duragrid - Subsea Impact Protection; ROV skid plates

- Duragrid HD Grating – impact protection (dropped object) – chillers, after-coolers

- Duragrid HD Grating – Boat Landings & Jacket grating

- Duragrid HD Grating & EXTREN Plate- Rig Movement Mats on ice roads

- Duragrate – Personnel Protection- Machinery

- Duragrate - Subsea Impact Protection, Boat Landings & Jacket Grating

- Duratread - Landing covers & replaceable anti-slip stair tread covers - w/wo words.

- Safrail Handrail – Round or Square- numerous configurations

- Safrail – Handrail/Lighting Fixtures

- Safrail /EXTREN tube - Pole Lighting

- Safrail – EXTREN tube – Instrument panel supports

- Safrail - Kickplate – 4 or 6 inch on FRP Handrails or Steel Handrails

- Safrail – Ladders; Ladders w/cages; diamond rung ladders

- EXTREN Plate – Gritted & bonded to grating for solid deck

- EXTREN Plate – Signs – plain or gritted (“Use Handrails” reminder signage)

- EXTREN Plate – Penetration Covers (typical small)

- EXTREN Plate- Covers - Trip protection – cutouts for instrument stands

- EXTREN Plate – Transition Plates between flooring elevation variance

- EXTREN Plate – Load dispersion- lay down- heavy trolley loads on grated surfaces

- EXTREN Plate – Instrumentation boxes- rust free enclosures.

- EXTREN Plate – Plate for control panels

- EXTREN Structure – Hop-ups; small access structures, ship stairs

- EXTREN-F Section – Kickplate - attaches to grating

- EXTREN Plate – Gritted & bonded to grating for solid deck

- Safplank – Wind-walls

- Safplank – sunshade/roof/cover

- Safplank - Storage shelves or mezzanine flooring

- Durashield – Extreme climate building cladding- Arctic or Desert

- Durashield – Equipment encloses- valve & pump boxes – extreme environment

- Durashield – Buildings, Covers

- Durashield – Mast/Derrick enclosures

- Composolite - Green water barriers – protection from sea spray

- Strongwell Ballistic Panels – Resists hand gun penetration

- Strongwell Storm Panels – lightweight protection for glass during high wind